In between all the Legnum work, I managed to crack on with the pulley and shaft some more.

Started with boring the pulley to size

Nearly 20mm.

Started doing final cuts on the shaft.

Machined the shoulder down to size.

Ready to be pressed together.

Pressed together and put back in the lathe to machine down the pulley boss.

I noticed after pressing the pulley onto the shaft, the bearing wasn’t quite able to slide on, a bit more needed to be machined.

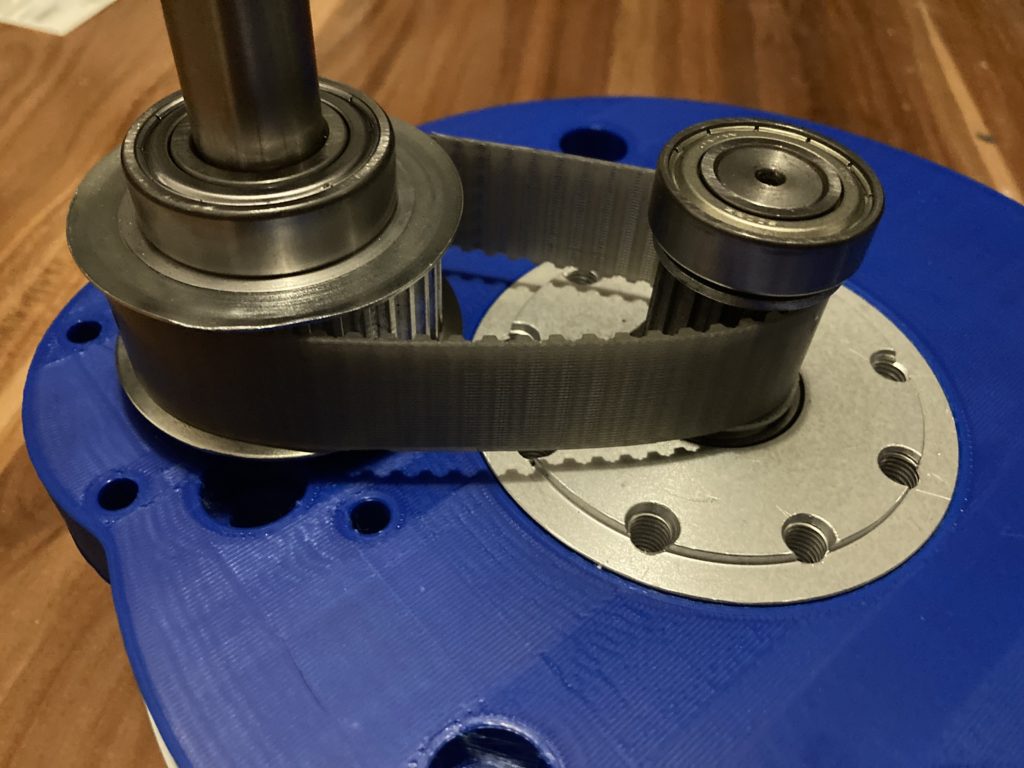

Finished and placed into the prototype.

Tension is horrible, but I’ll correct it by moving the bearing out 2mm further.

Quick video to show it spinning and the slackness, plus a quick view of the compressor wheel spinning.