It bucket rain today and flooded most of my outside work space, so I retreated inside and worked on designing some parts to make in the future, like the weapon gearing.

The weapon first stage gearbox needs designed, so a quick bit of cad work produced this, the front bearing block which houses two 22x10x6 bearings and captures the ring gear.

Front side has sunken bolt holes to bolt the whole assembly together.

Putting the Banebots P61 4:1 parts into the front block.

With this done, it’s time to design the rear block for the motor.

Designed this to center the motor with the ring gear, capture the motor screws and align everything together.

Ready to assemble the two halves.

Screws are oversized, but will order smaller ones once it is all finalised.

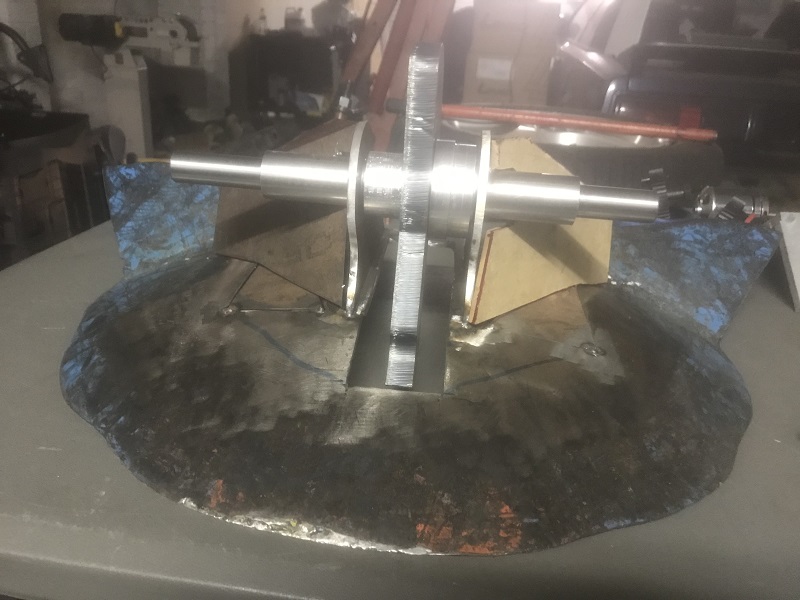

Printed out a shaft to work with the hex output for the Banebots.

Next up I printed some HTD5 pulleys, a 16T for the motor gearbox and both a 30T and 32T to play around with what works best for the weapon end.

Running the calculations, the 32T is likely going to be the best one to use as it gives a neat 8:1.

Till next time.